Claus process

The Claus process is a catalytic chemical process for converting gaseous hydrogen sulphide (H2S) into elemental sulphur (S).[1] [2][3] The process is commonly referred to as a sulfur recovery unit (SRU) and is very widely used to produce sulfur from the hydrogen sulfide found in raw natural gas and from the by-product sour gases containing hydrogen sulfide derived from refining petroleum crude oil and other industrial facilities.

There are many hundreds of Claus sulfur recovery units in operation worldwide. In fact, the vast majority of the 66,000,000 metric tons of sulfur produced worldwide in 2006 was by-product sulfur from petroleum refining and natural gas processing plants.[4]

Feed gas composition

Claus unit feed gases have a wide range of compositions. Most of the feed gases are originate from absorption (chemistry) processes using various solvents to extract hydrogen sulfide from the by-product gases of petroleum refining, natural gas processing, tar sands processing, coal gasification, smelters, coke ovens and other industries. The absorption processes used for that purpose include amine gas treating, Rectisol and Selexol to name a few.

In addition to hydrogen sulfide extracted from by-product gases by an absorption process, petroleum refineries also derive hydrogen sulfide from the steam distillation of wastewaters containing dissolved hydrogen sulfide. Those wastewaters are referred to as sour water and the steam distillation of those wastewaters is referred to as sour water stripping.

The table below provides typical analyses of the Claus feed gases obtained from amine gas treating and from sour water stripping:

| Component | Mol % | Wt % | Component | Mol % | Wt % |

|---|---|---|---|---|---|

| From an amine process: | From a sour water stripper: | ||||

| H2S | 82.1 | 80.8 | H2S | 26.7 | 40.2 |

| CO2 | 11.9 | 15.1 | CO2 | 2.6 | 5.1 |

| NH3 | nil | nil | NH3 | 39.4 | 29.7 |

| H2O | 4.0 | 2.1 | H2O | 31.3 | 25.0 |

| HC | 2.0 | 2.0 | HC | nil | nil |

| Notes: CO2 is carbon dioxide, NH3 is ammonia, H2O is water and HC is an abbreviation for hydrocarbons | |||||

Gases with an H2S content of over 25% are suitable for the recovery of sulfur in straight-through Claus process units (as described in the next section). Other process design configurations can be used to handle gases with lesser amounts of H2S.[5]

The amount of hydrogen sulfide derived from sour water stripping in a petroleum refinery is very much less than is derived from the refinery's amine gas treating facilities.

Process flow diagram and description

The Claus reaction to convert H2S into elemental sulfur requires the presence of one mole of SO2 for each two moles of H2S:

- (1) 2H2S + SO2 → 3S + 2H2O

To provide that ratio of components, the first step in the Claus process is the combustion of one-third of the H2S in the feed gas:

- (2) H2S + 1.5 O2 → SO2 + H2O

Combining equations (1) and (2), the overall process reaction is:

- (3) 2H2S + O2 → 2S + 2H2O

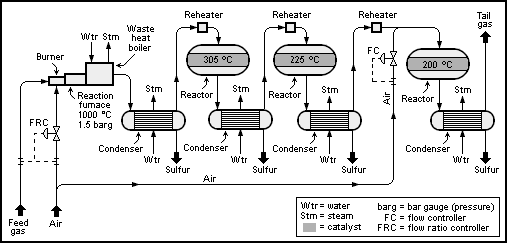

As shown in the schematic diagram below, the feed gas to a Claus process unit is burned in a reaction furnace using sufficient combustion air to burn only one-third of the H2S it contains. That is accomplished by using a control valve (called a flow ratio controller) to provide the required ratio of combustion air to feed gas.

The reaction furnace pressure and temperature is maintained at about 1.5 barg and 1,000 °C. At those conditions, the Claus reaction occurs thermally in the reaction furnace (i.e., without requiring any catalyst). About 70% of the H2S in the feed gas is thermally converted into elemental sulfur in the reaction furnace.

The hot reaction product gas, containing gaseous sulfur, is used to produce steam in a boiler (called a waste heat boiler) which results in cooling the gases. The gas is then further cooled and condensed in a heat exchanger while producing additional steam. The condensed liquid sulfur is separated from the remaining unreacted gas in the outlet end of the condenser and sent to product storage.

The separated gas is then reheated and enters the first catalytic reactor maintained at an average temperature of about 305 °C where about 20% of the H2S in the feed gas is thermally converted into elemental sulfur. The outlet product gas from the first reactor is cooled in another condenser while also producing steam. Again, the condensed liquid sulfur is separated from the remaining unreacted gas in the outlet end of the condenser and sent to product storage.

The separated gas from the second condenser is sent to another reheater and the sequence of gas reheat, catalytic reaction, condensation and separation of liquid sulfur from unreacted gas is repeated for the second and third reactors at successively lower reactor temperatures. About 5% and 3% of the H2S in the feed gas is thermally converted into elemental sulfur in the second reactor and third reactors, respectively. For a well-designed and operated Claus sulfur recovery plant having three catalytic reactors (as shown in the flow diagram), an overall conversion of at least 98% can be achieved. In fact, the latest modern designs can achieve up to 99.8% conversion of hydrogen sulfide into product sulfur that is 99+% saleable bright yellow sulfur.

The remaining gas separated from the last condenser is referred to as tail gas and is either burned in an incinerator or further desulfurized in a tail gas treatment unit (TGTU).

Reheat methods

The various methods used for the reheating required upstream of each catalytic reactor include:

- Direct gas-fired heaters using fuel gas and designed to operate at sub-stoichiometric conditions to prevent any oxygen (O2) from getting into the reactors which can damage the catalyst.

- Gas-to-gas heat exchangers in which cooled gas from a condenser exhanges heat with the hot gas from the upstream reactor.

- Steam-to gas heat exchangers in which the cooled gas from a condenser is heated with high-pressure steam.

Other design features

Older Claus sulfur recovery units were designed using only two catalytic reactors. Such units will typically convert only about 97% of the H2S in the feed gas. Because of stringent environmental regulatory requirements in the United States of America as well as many other nations, many of those older units have been upgraded to include three reactors. The tail gas from those that have not been upgraded is very probably desulfurized further in a tail gas treatment unit.

When the feed gas to a Claus unit includes ammonia and hydrocarbons (such as in the overhead gas from a petroleum refinery sour water stripper), special designs of the reaction furnace burner are available to provide complete combustion of those feed gas components.

To obtain higher reaction furnace temperatures and/or reduce the gas volume to be processed, pure oxygen may be used to enrich the reaction furnace combustion air.

Catalyst

The catalytic reactors each contain a bed of catalyst with a depth of about 90 to 120 cm. The most widely used Claus reaction catalyst is porous aluminium oxide (Al2O3), commonly referred to as alumina. [6] [7] [8]

The alumina catalyst owes its activity to a very high surface area of 300 m²/g or higher. About 95 % of that surface area is provided by pores having diameters of less than 8 nm (80 Angstroms).

The catalyst not only increases the kinetics (i.e., the rate of reaction) of the Claus reaction equation (1), but it also hydrolyzes the carbonyl sulfide (COS) and carbon disulfide (CS2) that is formed in the reaction furnace:

- (3) COS + H20 → H2S + CO2

- (4) CS2 + 2H20 → 2H2S + CO2

The H2S formed as per the hydrolysis equations (3) and (4) is then converted into elemental sulfur as per the Claus reaction (1). Most of the hydrolysis occurs in the first Claus reactor.

Other Claus catalysts based on titanium dioxide (TiO2) are also used. The titanium dioxide catalysts are produced from anatase, one of the three naturally occurring mineral forms of titanium dioxide. They are also called titania catalysts and are said to be more resistant to thermal aging than the alumina catalysts. They are also said to have a higher activity for the hydrolysis of COS and CS2 which allows the first Claus reactor to operate at lower temperatures compared to alumina catalysts.[8] However, they are significantly more expensive than the alumina catalysts.

History

In nineteenth century, there were many alkali manufacturing plants in England producing sodium carbonate (Na2CO3) by the Leblanc process. The original Claus process was developed by Carl Friedrich Claus, a chemist working in England, for the purpose of recovering sulfur from the waste calcium sulfide (CaS) generated by the Leblanc process. As a catalyst, he chose a bog iron ore and later bauxite (a mineral with a high alumina content).[9] In 1883, Claus was granted a British patent for the process.[8][9][10]

During the next 53 years, the Claus process underwent several minor modifications. In 1936, I.G. Farbenindustrie a (German conglomerate of chemical companies) introduced a modification of the process that utilized a thermal conversion step followed by catalytic conversion steps, which is the basically the concept currently used in modern Claus sulfur recovery units.

References

- ↑ Gary, J.H. and Handwerk, G.E. (1984). Petroleum Refining Technology and Economics, 2nd Edition. Marcel Dekker, Inc.. 0824771508.

- ↑ Fundamental and Practical Aspects of the Claus Sulfur Recovery Process P.D. Clark, N.I. Dowling and M. Huang, Alberta Sulfur Research Ltd., Calgary, Alberta, Canada

- ↑ The SuperClaus process

- ↑ Sulfur production report by the United States Geological Survey

- ↑ Gas Processors Suppliers Association(GPSA) (1987). Gas Processors Suppliers Association Engineering Data Book, 10th Edition. Gas Processors Suppliers Association. (Volume II, Section 22}

- ↑ The Role of Claus Catalyst in Sulfur Recovery Unit Performance Terry McHugh and Ed Luinstra, Porocel Corporation, Houston, Texas, USA

- ↑ Claus Process (Sulfur Removal)

- ↑ 8.0 8.1 8.2 Arthur Kohl and Richard Nielson (1997). Gas Purification, 5th Edition. Gulf Professional Publishing. ISBN 0-88415-220-0.

- ↑ 9.0 9.1 Howard F. Rase (2000). Handbook of Commercial Catalysts:Heterogeneous Catalysts, 1st Edition. CRC Press, pages 240 and 242. ISBN 0-8493-9417-1.

- ↑ British patent 5,958 (1883)